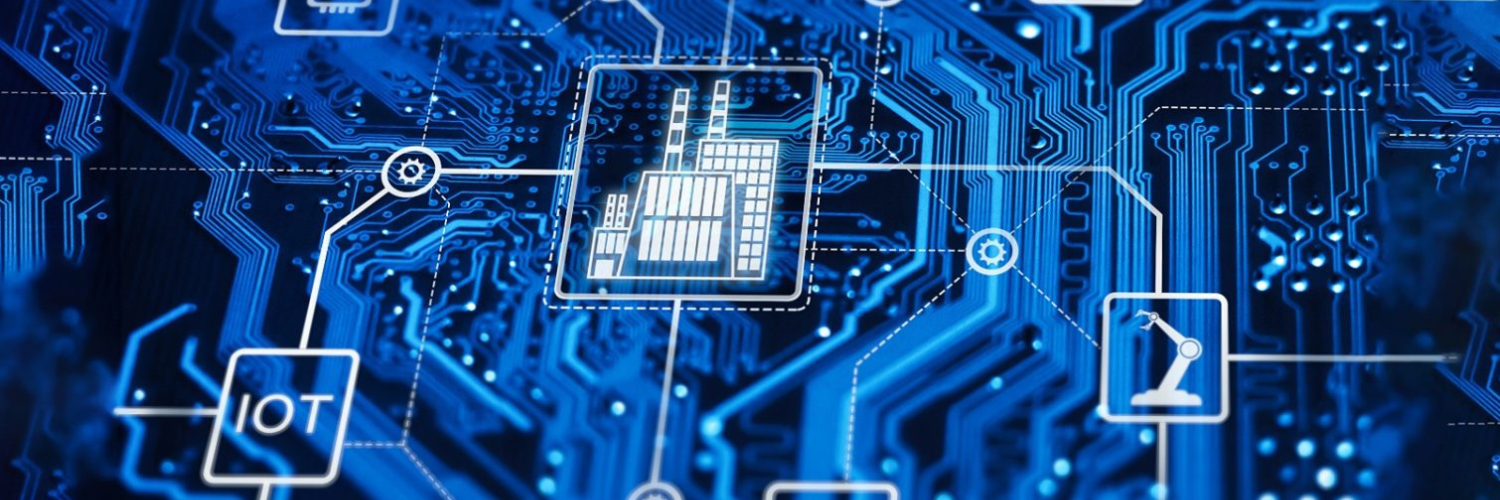

One of the biggest industries in the world, manufacturing, cannot but be influenced by digital technologies. The Internet of Things is becoming an integral part of our everyday lives has a growing influence on production enterprises, by transforming businesses and their operational processes, and creating smart factories.

In fact, manufacturing is the sector that has been most affected by IoT, with a potential economic impact (per year) growth from the current $3.9 trillion to $11.1 trillion by 2025.

What is IoT?

Industrial IoT is a system of interconnected industrial assets (machinery, equipment, vehicles, warehouses, shop floors, inventory, etc.) with embedded software and built-in sensors (hardware) for collecting and exchanging data.

Manufacturers can control such smart assets via a single IoT platform (or multiple interconnected ones), save the data on the cloud, and extract valuable insights.

Why is it gaining so much attention?

IoT is the tool for connecting and integrating the physical and digital worlds. And while this seemed impossible only decades ago, nowadays it has penetrated most aspects of our life.

Industrial IoT technologies accelerate productivity, minimize downtime, and make working conditions safer for employees, thus, providing a competitive edge for companies. And these are only some examples.

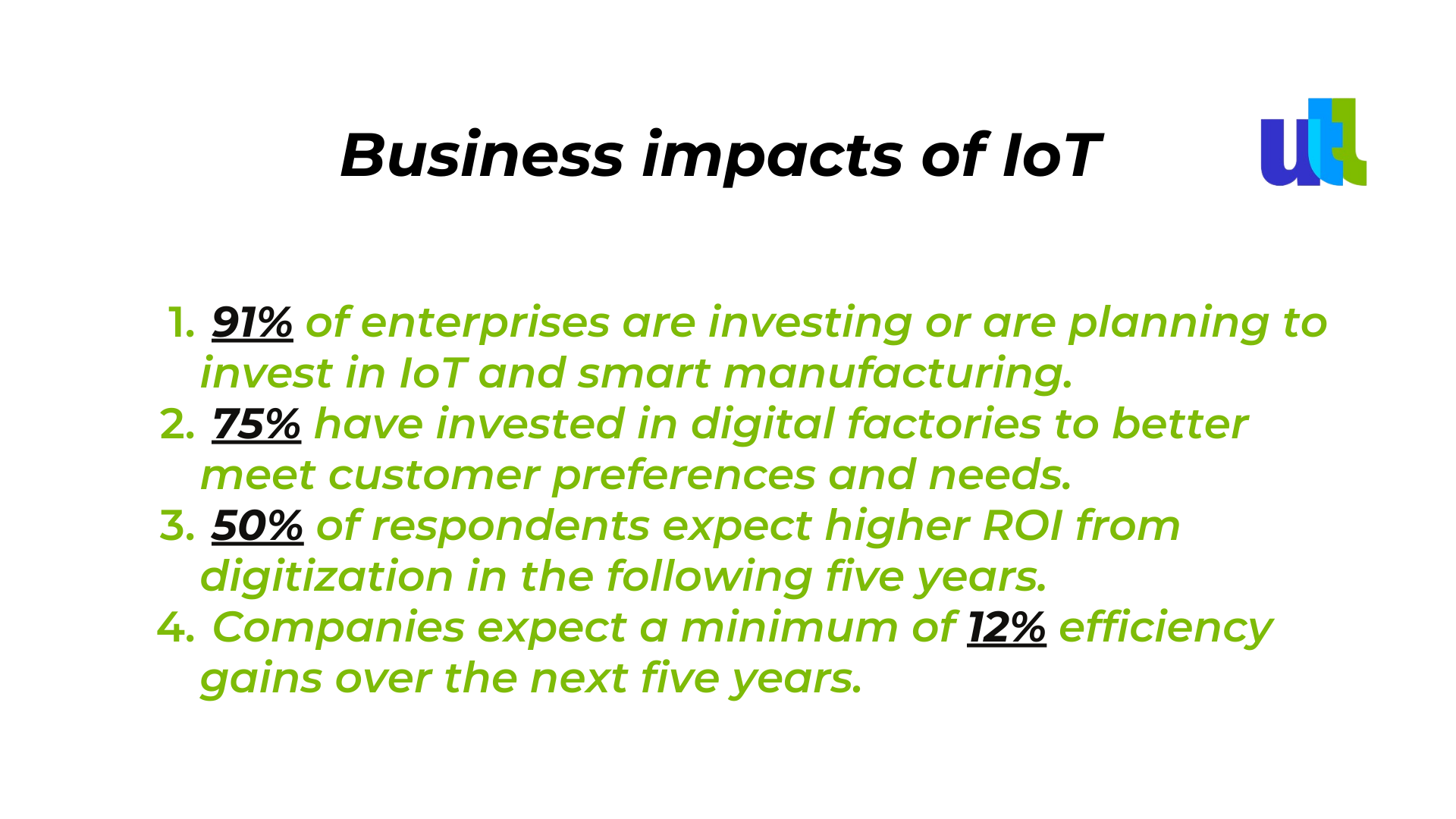

Business impacts of IoT

The implementation of industrial IoT solutions is one of the key goals for numerous physical businesses. A PwC survey (Germany) has revealed the following results:

In general, IoT is revolutionizing three core aspects of manufacturing by bringing innovation into traditional processes:

- Shop floor operations

Sensors embedded into IoT hardware collect real-time metrics on operational conditions and the state of spare parts. The data is then sent to the cloud platform for analysis, and the results are displayed in a user application, providing shop floor managers with a detailed overview of the production process.

Wearable IoT devices can track the health conditions and location of industrial workers operating in hazardous environments, also improving their safety levels.

- Supply chain

IoT sensors ensure end-to-end control of the manufacturing supply chain. Supply chain transparency is of great assistance for managers who want to develop and support seamless processes in enterprises.

- Remote and third-party operations

IoT manufacturing solutions enable the monitoring of all distributed and outsourced processes. This, in turn, is the best way of ensuring that produced goods comply with set standards.

Smart cities: is it the future?

Smart cities are quickly expanding and there is a growing need for connected IoT solutions that support the management of urban infrastructure, parking and traffic, electric vehicle charging, waste management, information sharing, and safety&security services. Of course, such demand growth for smart city technologies and IoT smart city solutions is caused by fast urbanization.

But what about industrial or smart city IoT examples?

1. Smart meters for utilities

IoT sensors in electricity/water/gas/heat meters send precise data to the supplier’s back office for tracking consumption in real-time.

2. Smart road signs

Digital monitoring of signs provides increased security and massive savings, avoiding manual inspection. It also allows to:

- Reduce man hours on controlling the signs

- Reduce transportation costs

- Increase security in traffic

3. Smart pest removal

IoT-powered pest traps digitize the manual work with small sensors and real-time notifications. This provides a full overview of the traps and improves the ability to take early action against the pests.

4. IoT smoke detectors

IoT-powered smoke detectors communicate digitally in case they detect smoke, while also providing information about temperature and battery levels.

5. Smart climate control

Tiny IoT devices can monitor the indoor climate and automatically notify about any changes in the air quality or temperature.

6. Traffic and noise monitoring

Intelligent provides valuable insights (air pollution, noise levels, traffic intensity, etc.) that can be used for better infrastructure planning.

7. Production sites

By simply installing IoT hardware with trackers on critical production machines, you can collect lots of useful data and get the machines to notify you well in advance before they need service.

8. Efficient logistics

With the help of IoT, logistics companies can equip their containers with smart sensors so that they are always tracked and safe. Such IoT hardware solutions also allow the supplier to provide new services, to streamline their logistics and inventory management.

9. Tracking machinery and equipment

With IoT trackers, tools and equipment on construction sites can always be tracked and localized, while the tiny sensors will provide useful data that can be then used for optimizing maintenance plans.

10. Smarter waste management

For example, by installing IoT sensors in the bins, the garbage collectors can measure and communicate remotely the fill level in every container and use this data for better route planning. This, in turn, helps better route planning and delivers significant savings by lowering transportation costs, and CO2 emissions and cutting working hours.

11. Healthcare solutions

For example, with smart trackers inside watches and bracelets, healthcare professionals and caregivers can easily locate any missing dementia patient.

12. Digital moisture meters

By installing small IoT hardware on floors and walls, service employees can read the moisture meters remotely, without having to visit the customer.

Bottom line

The shift toward Industry 4.0 is evident in the manufacturing industry. Manufacturers are eager to embrace smart manufacturing, moving toward new levels of interconnected and intelligent manufacturing systems.

If you are a manufacturer who wishes to grow exponentially in the next years and is looking to develop mind-blowing IoT-enabled solutions, talk to us.

Book a consultation with our IoT experts from Utah.

For free consultation about IoT experts click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Sofia Kutko

2023-04-05