The COVID-19 pandemic has taught us a tough lesson on the importance of having strong supply chains. Lockdowns and closed borders caused big problems, leading to not having enough important medical supplies and other essential items. This situation showed that businesses need to think differently about their supply chains to handle future crises better.

Having a resilient supply chain means a business can bounce back from surprises and keep things running smoothly. Companies with flexible supply chains, who work well with others, and use technology smartly were able to handle the pandemic's challenges better. They could quickly find new suppliers and adapt to new customer needs, while those who relied too much on one supplier or country struggled a lot.

The pandemic highlighted the need for businesses to work closely with everyone involved in their supply chain. Sharing up-to-date information helps spot problems early and fix them quickly. We've learned that supply chains are always evolving and need constant attention and improvement to avoid global shortages.

Now, more than ever, it's crucial for businesses to make their supply chains strong enough to handle future problems. This means being prepared, adaptable, and proactive is key to success in a world that's still recovering from the pandemic's effects.

Enhancing supply chain resilience post-pandemic

In the throes of the global COVID-19 pandemic, the many industries has faced unprecedented challenges. As we emerge into the post-pandemic era, the question that looms large is: How can the industry fortify its supply chains to survive such shocks in the future? The answer lies in a holistic, multi-dimensional strategy focused on resilience.

Increase transparency

The cornerstone of a robust supply chain is transparency. This encompasses the ability to trace the journey of products from manufacturers to consumer. Implementing advanced traceability systems ensures that companies can swiftly pinpoint and correct issues, be they related to quality control or supply disruptions. Such systems not only strengthen consumer confidence but also enhance the responsiveness of the supply chain to unforeseen events.

Enhance collaboration

Shared digital platforms can facilitate real-time tracking, risk identification, and collective mitigation strategies, thereby creating a more unified and resilient supply chain ecosystem.

Adopt digital technologies

In the digital age, technology is the great enabler. The adoption of Internet of Things (IoT) devices, blockchain technology, and artificial intelligence can transform supply chain operations. These technologies offer precise tracking, predictive analytics for demand forecasting, and smart decision-making tools that can optimize the entire supply chain.

Increase supply chain visibility

Visibility is not just about tracking movement but also about foreseeing potential bottlenecks and addressing them. Employing predictive analytics and data-driven insights can help companies anticipate and navigate disruptions, ensuring that quality and safety standards are upheld, and customer expectations are met.

Implement sustainability initiatives

Sustainability and resilience go hand in hand. A supply chain with a strong commitment to sustainable practices is inherently more flexible and future-ready. This involves embracing eco-friendly packaging, reducing waste, investing in renewable resources, and adopting sustainable practices. Innovations in this space not only contribute to a healthier planet but also ensure long-term viability and cost savings.

Go-to-market versatility

The pandemic has rewritten the rules of engagement with the market. Versatility in approach – from pricing strategies to delivery channels – has become a necessity. With the rise of e-commerce and digital sales channels, companies must develop a flexible, omnichannel presence to meet customers wherever they are.

End-to-end supply chain management

Diversification of the supply base, especially with an emphasis on local sourcing, can significantly mitigate risk. By broadening the supplier network and maintaining strategic stores, companies can avoid the pitfalls of over-concentration and ensure a steady flow of goods even during supply shocks.

Identifying and mitigating hidden supply chain risks

Today’s products, especially tech-driven ones, involve a complex mix of parts and materials. A typical example is our cars, which come packed with high-tech electronics — from the touchscreens to the tiny processors that run everything. To make these, car companies need a whole host of specialized skills, often found in different parts of the world.

Take, for example, the specialized chemicals used in vaccines and therapies; many come from places like South Korea and China. Companies tend to rely on suppliers who are experts in just one thing. This can be great for getting the best tech into products, but it also creates a big risk. If something goes wrong with that one expert supplier, it can throw a wrench in the whole production process.

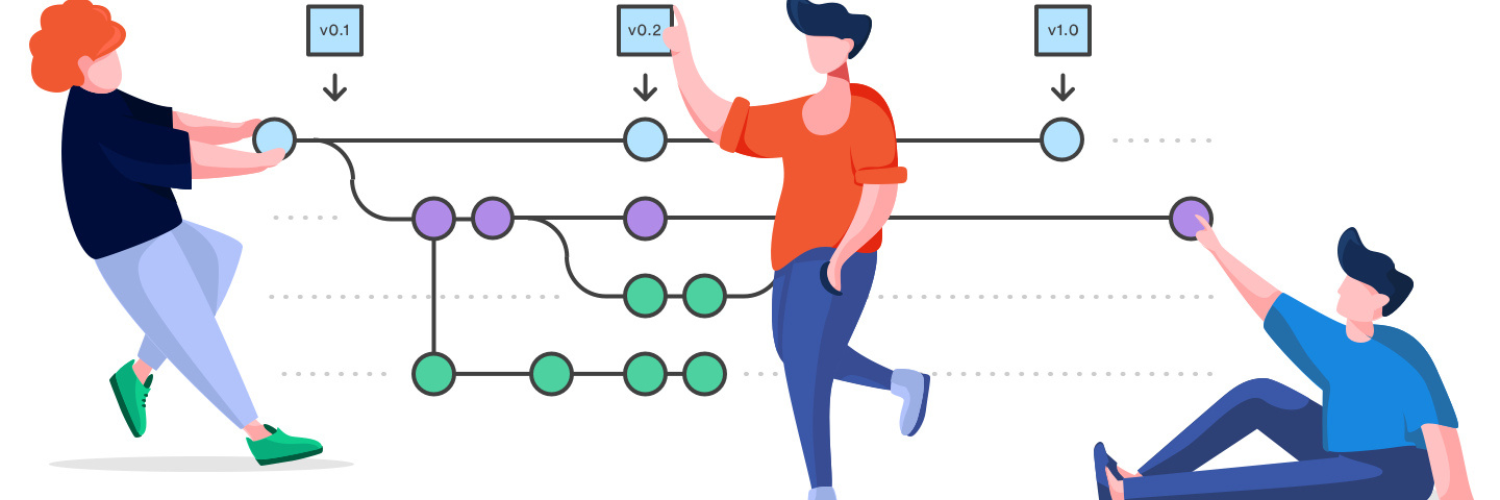

To protect themselves, companies need to really know their supply chain inside out. This means understanding not just who their main suppliers are but all the other businesses their suppliers depend on, plus how the parts get from one place to another. This detailed mapping can take a lot of time and money, which is why it’s often overlooked, but not doing it can cost even more if a surprise problem occurs.

Companies should sort their suppliers into categories based on how much of a risk they pose. They can look at how badly they’d be affected if they lost a supplier, how long it would take for that supplier to get back on track, and if there are other options available. This kind of planning can make all the difference in an emergency.

One way to reduce risk is to not put all your eggs in one basket. Instead of relying on a single country or supplier, companies are looking to get their parts from various places. After trade issues between the U.S. and China, many companies are spreading out their manufacturing to other Asian countries as well.

It's usually easier to find new sources for simple products than for high-tech ones. Building up new supplier networks takes a lot of time and effort, as China’s own development has shown. And even if companies start making things in new places, they still need to keep a connection to China because of its huge role in the global market.

Companies are also keeping some extra stock just in case, which is a change from the usual practice of keeping inventory low. This safety stock can be a safeguard against sudden shortages but also means tying up cash in stock that might not be used right away.

In conclusion, making supply chains stronger means being proactive about the risks. Companies need a balanced approach that involves getting to know their supply chain deeply, spreading out their sources, and having some extra supplies on hand. This way, they can keep their operations smooth and stay competitive no matter what happens in the world.

Embracing process innovation for a robust supply chain

With such changes comes the chance to rethink and improve how things are done, breaking away from old habits and introducing better equipment and more efficient workflows.

Now, let's talk about technologies that are changing the manufacturing game:

- Automation is becoming more common and affordable. This means robots and machines can take over more tasks, especially in places where they need to keep workers safe, like during the pandemic. This is even encouraging some businesses to bring production back to countries where labor costs are higher.

- New processing technologies are making manufacturing cleaner and less wasteful. For example, the latest chemical processing equipment uses less energy and creates less waste, which is good for the planet and the bottom line.

- Continuous-flow manufacturing is another game-changer. It's especially useful for making generic drugs because it relies less on imported ingredients. This method can quickly adapt to make different drugs as needed, without a big factory or lots of raw materials on hand.

- Additive manufacturing, or 3D printing, is allowing companies to make complex parts quickly and locally, reducing the need to rely on distant suppliers.

All these innovations mean that businesses can operate smaller, more local factories that are less likely to be disrupted by global issues.

Technology platforms for supply chain resilience

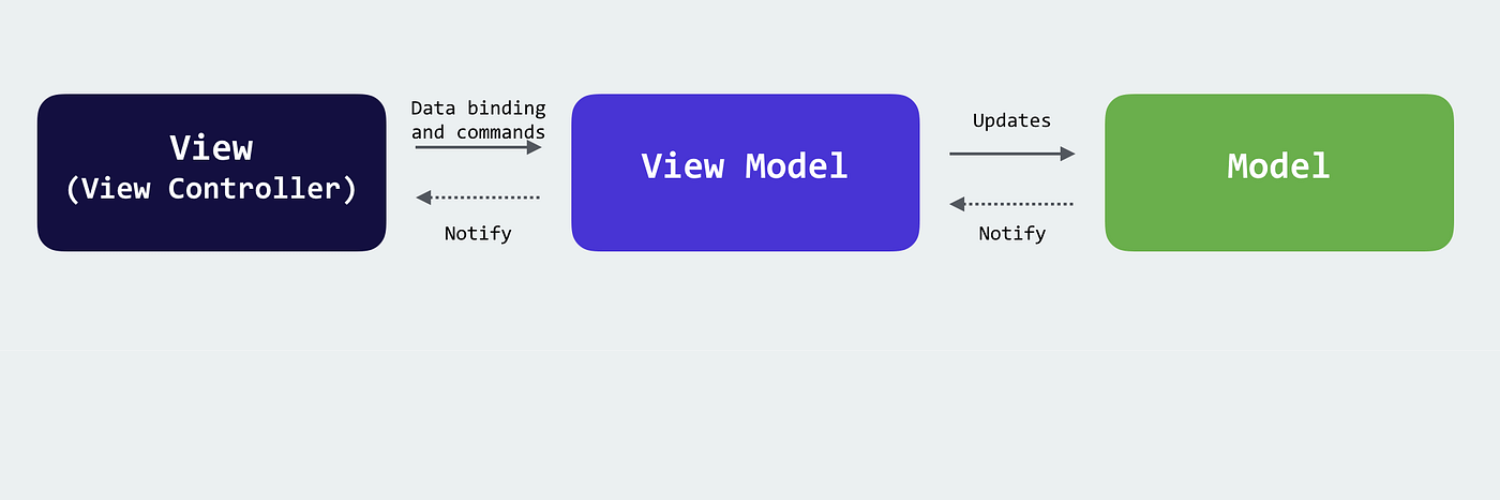

Modern technology platforms can strengthen supply chains in several ways:

- They help create a seamless shopping experience for customers, whether they're online or in-store.

- They support better planning across the business, bringing together different departments to respond quickly to market changes.

- Cloud-based systems make it easier for every part of the supply chain to connect and share information.

- Flexible and adaptable tech architecture lets businesses reconfigure their systems as needed, much like using LEGO™ blocks to build different structures.

Streamlining purchases with smart ERP integration

Leveraging an Enterprise Resource Planning (ERP) system can revolutionize how businesses manage their purchasing by minimizing wasteful spending and eliminating the risks of over or under-ordering. With sophisticated forecasting based on historical data, ERP systems enable more accurate predictions of what and how much needs to be ordered, and when.

This technology brings order to the complex web of suppliers, facilitating the selection of the best vendors at the right time while keeping the business agile. Should a supplier be caught in the midst of a pandemic surge or adverse weather conditions, the system swiftly redirects orders to a safer source, ensuring continuity. The agility provided by ERP systems is essential, particularly when relying on a limited number of suppliers could lead to vulnerabilities due to unexpected disruptions.

ERP tools automate the diversification of the supplier network and assist in emergency planning, offering a birds-eye view of supplier performance, which is crucial for sustained improvement and resilience in the supply chain.

The future of supply chain management

Artificial intelligence and machine learning are transforming supply chain management. They're helping companies predict what they'll need and when, making sure they don't run out of stock or have too much just sitting around. These tools are also streamlining shipping and delivery, cutting costs and improving service.

Collaboration is key, too. The pandemic has shown us that being able to work together, even when we're apart, is vital. And with the right digital tools, sharing information with suppliers and partners becomes safer and more reliable.

Cybersecurity is more important than ever, with attacks on the rise. A solid, up-to-date tech platform is the best defense against these threats, helping to protect businesses from the unexpected.

In short, building a resilient supply chain means being ready for anything. It means using the latest tech to keep a close eye on every step of the process and working closely with everyone involved. That way, businesses can stay agile and keep delivering, no matter what the world throws at them.

Conclusion

As we conclude this exploration into fortifying supply chains in a post-pandemic era, it’s clear that resilience and agility are the new benchmarks for success. The pandemic has laid bare the vulnerabilities inherent within traditional supply chain models, compelling businesses to pivot towards digital transformation as a means of survival and competitive advantage.

Embracing digital innovation is no longer optional but a critical imperative. The deployment of advanced technologies like AI, machine learning, and IoT enables businesses to transition from reactive to proactive stances, effectively managing and even blocking disruptions. By integrating these tools, companies can enhance visibility, improve predictive accuracy, and automate key processes, leading to a leaner, more responsive operation.

As supply chains become more interconnected, the ability to share data and insights across the network becomes invaluable. Such collaboration paves the way for a supply chain that is not only smart and efficient but also one that can rapidly adapt to the ever-changing market demands and global challenges.

In essence, the journey towards a resilient supply chain is a continuous one, marked by strategic planning, adoption of new technologies, and a commitment to innovation. As businesses look ahead, the lessons learned during the pandemic will undoubtedly serve as a guide for building stronger, more resilient supply chains capable of withstanding the tests of time and turbulence.

For free consultation on supply chain challenges, click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Milda Butkeviciute

2023-11-29