Designing and building the Internet of Things hardware is always a treat. You will collaborate with hardware designers, create a prototype, run it by stakeholders, and develop an actual, tangible product fully compatible with your IoT environment.

Both hardware and software components are designed for IoT applications through a standard design protocol and integrated with a communications network in the end. However, there are a couple of key considerations that this article will discuss.

IoT hardware explained

However, what exactly is IoT hardware? What are these devices we constantly hear about lately?

In fact, you have more than likely been using IoT hardware in some form or another. There has been a surge in startup companies working on such projects and has shown no signs of slowing down. Let’s dive deeper into it.

A good example of how connected devices actually work is those of your smartphone and your smartwatch. After connecting your phone to your smartwatch, you can easily control any one of them through the other device: from messaging and scrolling through social media to setting an alarm and health control apps - all can be done because of their connection.

Another example is sending data. While you’re wearing a smartwatch, your steps, distance walked, heart rate, and other parameters will be transmitted back to your smartphone, then analyzed, and recorded for reference.

And this was the most basic concept. Nowadays, companies develop smart homes, connected vehicles, and security systems that offer much more. The opportunities for smart, connected hardware products are enormous. However, so are the product development challenges.

The main idea behind IoT hardware is to assist you in day-to-day living and make life more convenient.

IoT devices

Traditionally, in the context of IoT, a device refers to anything that attains information and transmits it.

For example, a temperature sensor within a refrigerated railcar. Devices may stand alone, or function in sync with other devices.

IoT hardware design

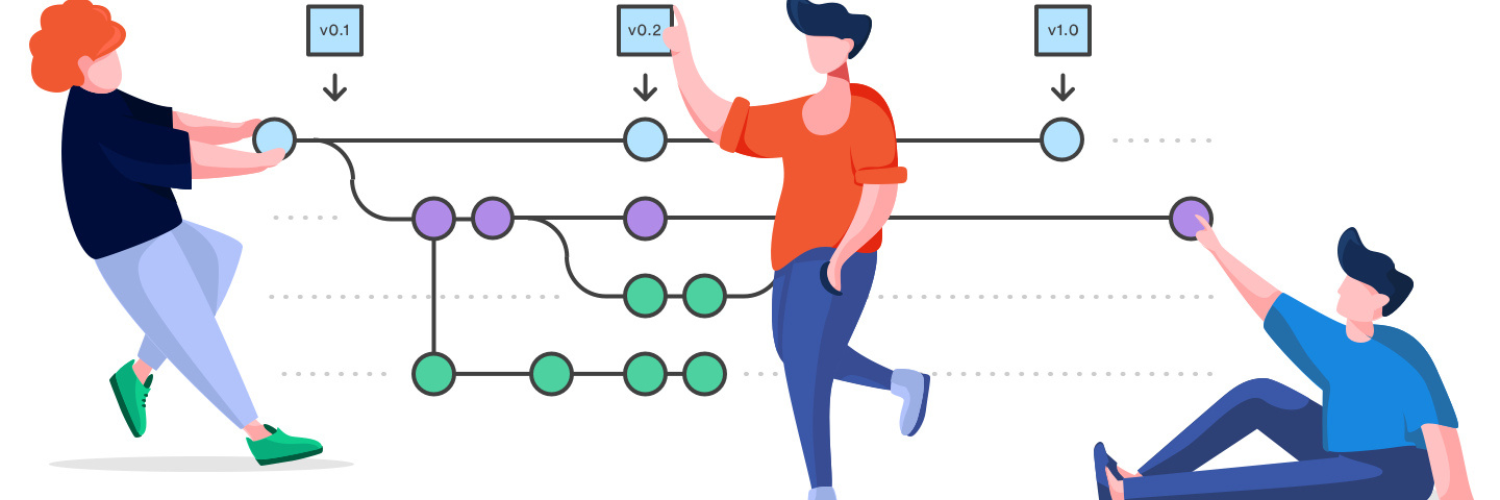

Hardware and software components are designed for IoT applications via a standard design protocol: specification development, conceptual design, prototype, multistep testing, and rollout of hardware and software integrated into a network.

Hardware design will require identification of performance requirements, also followed by specifications for each component – either commercially off-the-shelf (COTS) or customized designs – this will depend on the operating environment and the application to be used within it.

In hardware design, the main thing is a clear understanding of the customers' business requirements. You must consider every small detail and ensure that they correspond to the final goal.

Before starting, it’s important to make sure your team has the answers to the following questions:

- What are the physical signals to be measured?

- Should the sensors be connected to the cloud or with the help of a gateway device?

- How often should we collect the signals? And how fast the data should be transmitted?

10 stages of a successful IoT hardware design process

Although IoT products comprise software, firmware, and hardware components, 80% of the costs and development challenges arise from the last one. That is why it’s important to understand it in depth and follow the process diligently and consciously.

1. Conduct thorough product research and build the right team

Study all the details such as configurations, features, market gap, your target, competitors, etc. Then, take note of the existing skill set in-house and the knowledge and expertise you might need to form the outside.

2. The very first product design

This step is necessary to address the gaps between the desired design concept and the actual possible design. You will need to specify all the electronic functions and their interconnections.

3. Schematic circuit diagram

You might be wondering: what is it and what does it look like?

Well, the schematic circuit diagram primarily focuses on the high-level functionality of the product. The diagram enables you to consider the tiniest details and components, such as sensors, microchips, and resistors inside the future hardware.

4. Add on mechanical and industrial components

CAD (Computer-aided design and drafting) is a technology that replaces manual drafting with an automated process. It is widely used for designing mechanical and industrial components.

The objective is to scope the hardware design's value, function, and appearance of all components with the help of the right CAD tool.

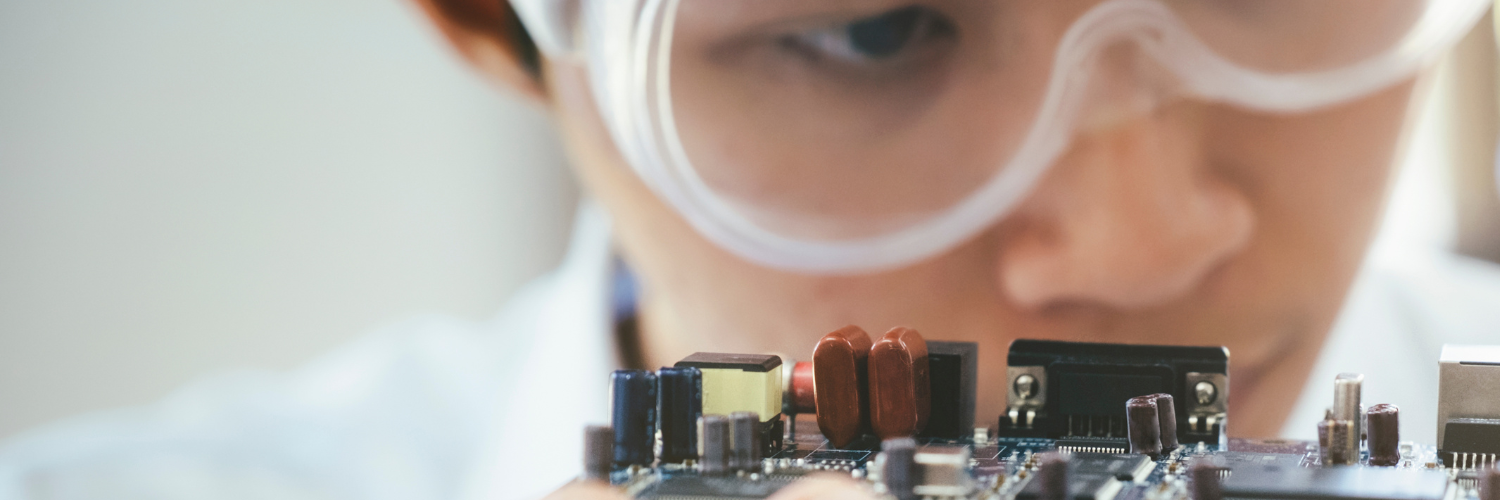

5. PCB design

PCB stands for Printed Circuit Board and is primarily used to mechanically support and electrically connect the components of future hardware.

There is one thing you should remember while starting your PCB design: the smaller the components, the more complicated the creation of the PCB layout is. The design will be even more complex if the product offers wireless connectivity.

6. The list of items and materials

Your next step is creating the final Bill of Materials (BoM). It is basically the list of all mechanical and electronic items to be purchased. Verify the document manually before reaching out to the best vendors.

7. Start the prototyping process

This step helps measure the feasibility of the product desired. It not only saves time and effort but also ensures the development process is quick and easy. Here you have two options: in-house prototyping or outsourcing.

8. DFMA design

Design for manufacturing and assembly simplifies the production complexity and keeps the overall costs low by proceeding with high-volume manufacturing and minimizing the number of product assembly steps.

9. Get down to hardware production

Once you have finalized your prototype and got approval from stakeholders, it is time to get down to making the hardware. At this stage, you still can identify and resolve any remaining issues in the design, along with fixing bugs.

10. Design and product final review

Perform multiple build tests to evaluate the design and whether your product is ready for mass production. Gather your first feedback and professional reviews.

By following these 10 critical stages of the IoT hardware design and development process you will have a high chance of actually succeeding in this competitive market.

The best design for your IoT project: what else is important?

IoT devices are highly specialized and are designed to operate within niche environments.

There is no "one-size-fits-all" approach to IoT hardware design and development projects. However, adopting standards-based IoT hardware requirements can save you time and monetary resources in the early stages of the development process.

As an IoT hardware and software development company, we take care of the entire development process - from idea conceptualization, prototype designing, and manufacturing design to firmware development and multistep quality controls.

At Utah Tech Labs, we help you make critical hardware design decisions, prevent most of the possible future issues, and deploy your final IoT solution.

IoT hardware development by Utah Tech Labs contact page.

For free consultation about IoT hardware development click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Sofia Kutko

2023-03-29