Introduction

The key to success in the complex web of international trade is supply chain optimization. Enter artificial intelligence (AI), a game-changing phenomenon that is rewriting supply chain management rules. AI's advanced algorithms and machine learning powers are ushering in a new era of strategic planning that is characterized by accuracy, flexibility, and vision. With the use of this technology, businesses may increase productivity, optimize resource allocation, and achieve new levels of efficiency.

The role of AI in supply chain strategy formation

Artificial Intelligence has a significant and diverse impact on supply chain strategies. Its capabilities go beyond simple automation; it provides profound understanding of intricate data sets. The consequences for the supply chain are immense because AI not only anticipates and reacts to changes in the market, but it also proactively develops tactics to foresee obstacles down the road.

AI's transformation of supply chain planning

The core of artificial intelligence's value proposition is its capacity to process vast volumes of data, identify patterns, and make remarkably accurate predictions. This translates into supply chain strategies that take logistical issues, consumer behaviour, and market volatility into account. Artificial intelligence (AI) can detect risks or opportunities that human planners would miss by using its predictive analysis of historical and current data.

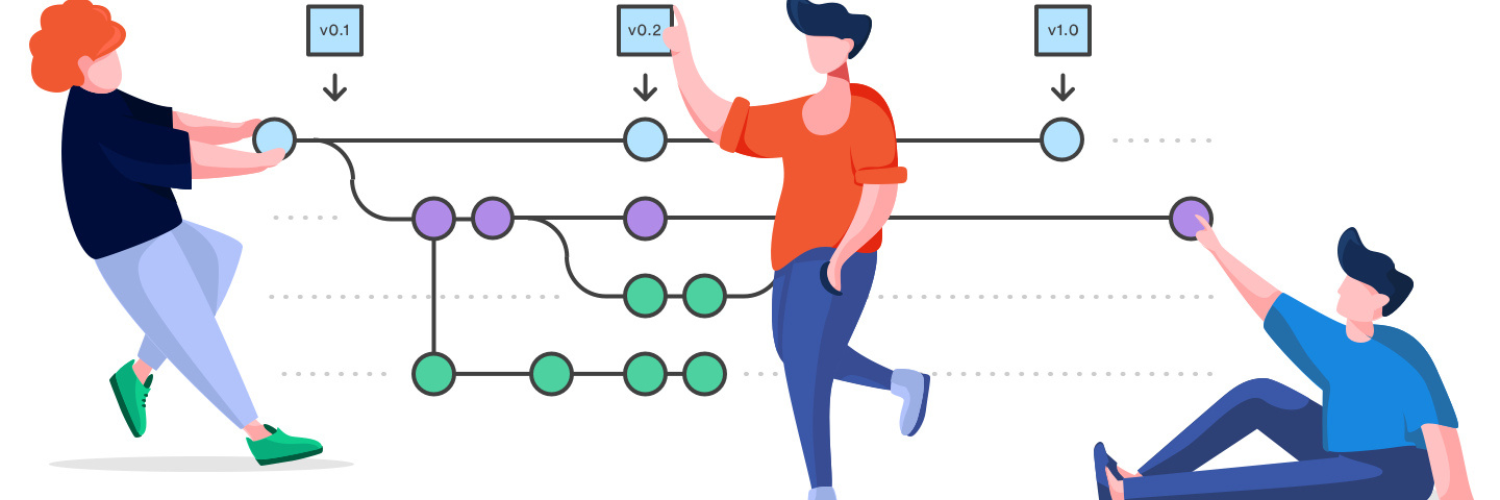

The significance of AI architectural progress

Another essential component is scalability, which enables AI systems to increase their capability as supply networks get more intricate. This is about adaptable learning, which is the foundation for AI's ongoing development, not only about processing capacity.

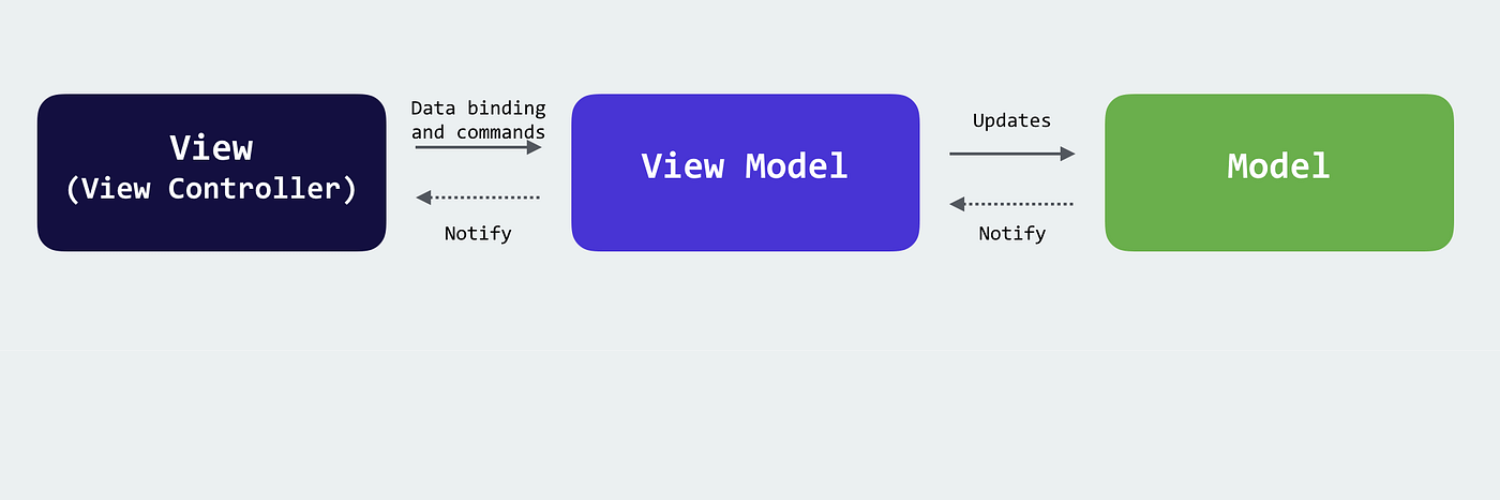

Deciphering AI in supply chain strategy architecture

The foundation of an AI supply chain strategy generator is made up of complex algorithms. It provides a comprehensive picture of the supply chain by integrating multiple components, including inventory levels, supplier performance measures, and consumer demand signals. This architecture guarantees the high actionability and comprehensiveness of AI-generated tactics.

Advantages of AI-powered supply chain planning

The industry is entering a new era of efficiency and strategic acumen because to the transformative effects of integrating Artificial Intelligence (AI) into supply chain planning.

Enhanced efficiency through automation

The notable increase in efficiency in supply chain planning is among the most noticeable effects of AI. One of AI's main features, automation, simplifies intricate procedures that formerly needed a lot of manual labour. Artificial Intelligence (AI) frees up human resources by automating repetitive operations like data input, inventory tracking, and order processing. This enables businesses to reallocate their workers to higher-value projects and strategic initiatives. This change reduces the amount of time it takes to get goods from the warehouse to the client while also relieving staff of the monotony of repetitive labor.

Strategic allocation of resources

Organizations can switch from operational management to strategic growth and innovation because to AI's capacity to automate and optimize. AI will take care of the day-to-day challenges of supply chain management, freeing up resources for companies to invest in growth, market research, and the creation of new goods and services. This tactical change may result in the identification of untapped markets, possible cost-cutting opportunities, and creative ways to satisfy client needs.

Precision in planning

Artificial Intelligence (AI) can improve supply chain disruption predictions, optimize stock levels, and estimate demand more precisely by evaluating enormous arrays of historical and real-time data. This accuracy reduces the possibility of stockouts or overstocking, two expensive scenarios. It also makes just-in-time inventory techniques possible, which minimizes waste and lowers holding costs.

Improved responsiveness

Reactivity is essential to maintaining competitiveness in the fast-paced economy of today. AI increases the agility of a supply chain, enabling businesses to react quickly to changes in the market, such as abrupt changes in customer demand or unanticipated bottlenecks in the chain. AI-driven solutions ensure that businesses may swiftly and without major delays adapt to changing circumstances by allowing them to dynamically change orders and redistribute inventory in real-time.

Consistency in execution

Artificial intelligence algorithms provide consistency and reliability, functioning without human biases and faults. This consistency guarantees that every stage of the supply chain is carried out with the least amount of deviation from the plan. AI technologies, for example, may control freight prices, maintain compliance with shipping laws, and continuously monitor carrier performance. This dependability guarantees that products are delivered accurately and on schedule, which is essential for upholding quality control and customer satisfaction.

Enhanced reliability

AI-powered solutions are more reliable in supply chain operations because they are always learning and getting better over time. They are able to identify trends that may point to equipment malfunctions or quality problems, and they can initiate repairs before these problems worsen and result in expensive downtime or recalls. Predictive maintenance makes ensuring that there are no unforeseen disruptions to the supply chain, which could result in lost sales or tarnished reputations.

In summary, supply chain planning powered by AI is a strategy shift rather than merely a technology advancement. Organizations may improve their existing operations and lay a solid platform for future development and innovation by leveraging the efficiency, accuracy, and consistency that AI delivers.

Challenges in AI supply chain strategy generators

There are obstacles, though, such as the possibility of a one-size-fits-all strategy that might not be appropriate for the requirements of every company. To make sure AI systems satisfy organizational requirements, they must be carefully examined and improved. Although generally high, the accuracy of AI-generated methods might vary, highlighting the necessity of human oversight.

The future of AI in supply chain strategy planning

AI's role in supply chain strategy will only continue to develop in the future. More sophisticated data processing will be made possible by developments in machine learning algorithms, opening the door to the development of more focused and nuanced tactics.

Conclusion

AI is transforming the It is critical that supply chain to new heights of strategic intelligence, not just making changes to it. Artificial Intelligence plays a vital role in supply chain planning, from improving decision-making to enabling real-time responsiveness. With AI, we can see a future in which supply chain management will involve more than just reacting to the current state of affairs; rather, it will involve anticipating the state of the world as it develops. This is a monument to innovation as we move forward.

For free consultation on the role of AI in supply chain strategy, click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Milda Butkeviciute

2023-12-22