Data exchange and automation are game-changing trends in the business world. The logistics sector is not an exception: new concepts, such as digital connectivity, interconnection, monitoring, and interoperability, have emerged as disruptive technologies.

Companies that rely heavily on logistics and shipping face numerous challenges in today’s business environment, especially considering the world supply chain crisis, labor and shipping shortages, increasing freight costs, increasingly complex international regulations, and changing customer expectations.

The good news is that technology helps to address most of these issues. The key is making sure the tech solution you choose is compatible with your business needs, existing challenges, and the current level of digitalization.

Once you have completed the basic digitalization steps, you can proceed with the implementation of advanced technologies that meet the unique needs of your logistics operations. By implementing connectivity throughout the entire organization, you provide your business with a great competitive advantage.

After all, nowadays, you simply cannot keep up with market demands without it.

Real-time Supply Chain Management

Real-Time Planning in the SCM context is the process of organizing all activities around gathering data without time delays, analyzing it, and taking fact-based real-time decisions.

By managing the supply chain effectively, companies reduce production costs, avoid shortages of raw materials, and deliver products to customers timely.

The game-changing technologies in supply chain management include but are not limited to artificial intelligence, IoT, cloud computing, advanced analytic tools, digital twins, and many more.

Benefits of supply chain automation

The advantages of automating your supply chain processes are numerous. Some of the most significant ones include:

- Automating manual tasks

- Minimizing human errors

- Increasing visibility and transparency

- Improved customer experience

Lost orders often mean lost customers. Data empowers businesses to detect and fix weaknesses in the supply chain before they become significant problems.

The universal truth about today’s customers is that they expect to receive their orders as soon as possible with outstanding customer service even in case some problems arise along the way. Supply chain automation serves customers in multiple ways: from automatically triggering order fulfillment to picking and packing the orders.

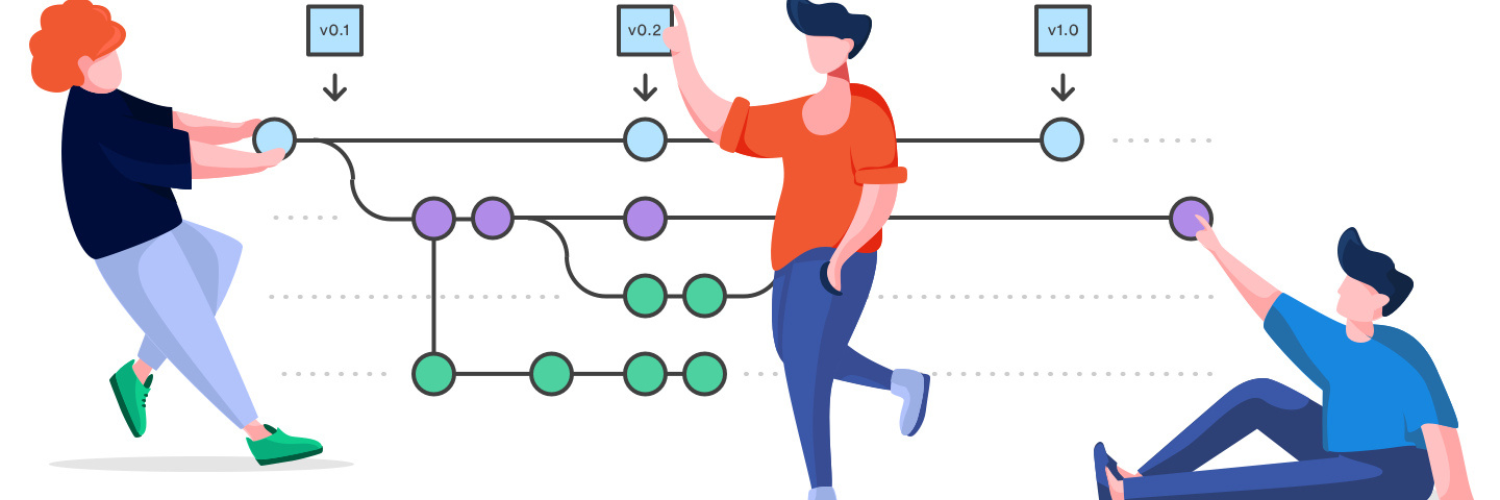

What is supply chain integration?

Supply chain integration (SCI) can be defined as the alignment of supply chain goals and policies along with the related information and physical connectivity:

- Alignment: shared goals among the elements of the supply chain, often aimed at reducing their costs, improving their performance, and ensuring consistency in the strategy pursued. The lack of alignment often results in difficulties in synchronizing the components of a supply chain.

- Connectivity: the information and physical flows between the nodes of the supply chain, including orders, tracking, inventory levels, as well as the modes and terminals involved.

Integrated supply chains have a lower risk of a lack of alignment. Connectivity usually relates to physical flows, while integration – to processes.

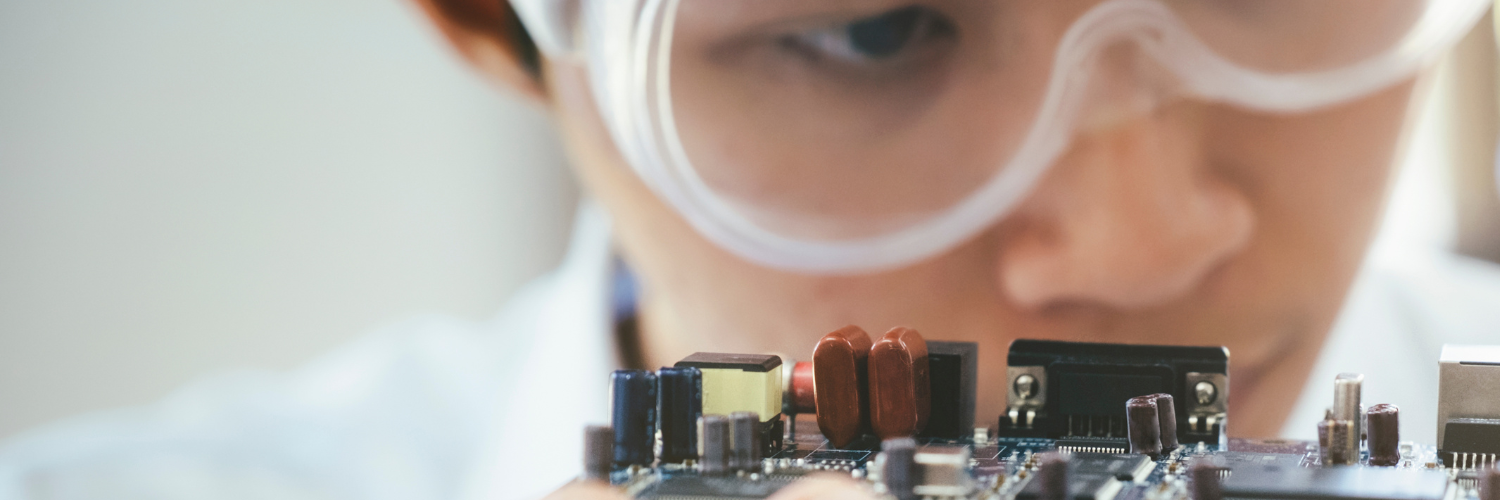

Connectivity in the warehouse

Connectivity in the warehouse allows you to be more productive with fewer employees. With a handheld device, a single warehouse employee can complete several processes in a minute: with Zebra scanners, barcodes, printers, and so much more. Other advanced possibilities include automatic identification and data capture (AIDC) technology, radio frequency identification, and box selection algorithms.

Connectivity in transport

Shippers and drivers communicate in real-time through a single platform. Furthermore, by combining the analytical capabilities of the systems, the most efficient route can be planned automatically, increasing the odds of on-time delivery. Multi-dimensional monitoring tool provides real-time information on your vehicles and notifies you of potential delays.

Mobile solutions integrated with AI functionalities and logistics software systems help you gain and maintain control over your shipping and delivery activities. Even when the supply chain is becoming more complex, and competitive, the demands are increasing.

The big possibilities of mobile connectivity

Logistics software is the answer for two critical processes: 1) receiving raw materials and inventory from suppliers, 2) sending products to customers. By implementing standardized, replicable processes that connect your supply chain, you save time and money while your SC becomes much more efficient.

That also explains why the logistics software market is expected to reach $18.31 billion by 2030 (Market Research Future).

As in the case of most business processes, a technology platform increases efficiency which results in higher revenues and profits. Additionally, logistics software provides companies with real-time information about the status of deliveries, inventory, and employees, thus, helping to reduce transportation expenses.

With technologies streamlining your business, you will be able to maintain high customer satisfaction and loyalty rates. At Utah Tech Labs, we help you get that all.

For free consultation about logistics connectivity and integration click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Sofia Kutko

2023-04-26