In the realm of supply chain logistics, a quiet revolution is taking place. Robotics, long present in the form of automated machinery and intricate sorting systems, is entering a new phase of collaboration with human workers. These new robotic systems, known as collaborative robots or "cobots," are designed to work alongside human employees, enhancing efficiency and productivity within the warehouse environment.

Cobots distinguish themselves by their ability to operate in direct conjunction with their human colleagues. Ready with state-of-the-art sensors and safety mechanisms, they are specifically engineered for interaction. This technology represents a significant departure from traditional automation, focusing on augmenting rather than replacing the human workforce.

The advent of cobots is not just an upgrade to existing systems—it's a re-envisioning of workplace collaboration. As cobots integrate into the daily flow of warehouse operations, they bring a unique blend of reliability and flexibility to tasks that were previously challenging to automate. This introduction will explore how cobots are making waves in the industry and reshaping the future of supply chain operations with a focus on cooperative human-machine dynamics.

Understanding cobots

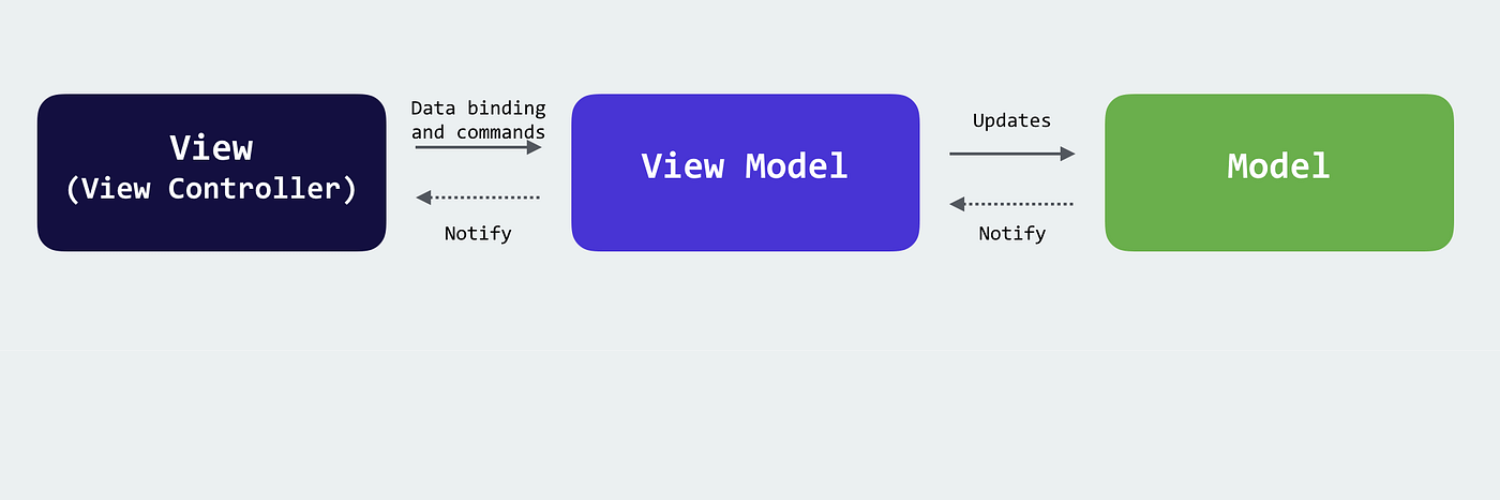

As we delve into the world of collaborative robots, or 'cobots', it's essential to understand what sets them apart from their predecessors in industrial automation. Cobots are a significant leap forward, designed to complement human workers rather than operate in quiet. Unlike traditional industrial robots that require safety cages and often work in isolation, cobots are built with collaboration in mind. They boast key features such as intrinsic safety mechanisms, flexibility, and ease of programming, which allow them to adapt to various tasks and work safely alongside human counterparts.

These technologies not only empower cobots to perform a wide range of tasks but also ensure a harmonious interaction with human workers, paving the way for a more integrated and productive workplace. As we explore the capabilities and contributions of cobots, it's clear that they represent not just a tool, but a collaborative partner in the evolving narrative of industrial automation.

The role of cobots in warehousing

In the landscape of warehousing, cobots are making their mark not by overshadowing human effort but by enhancing it. These robotic allies are currently engaged in a variety of tasks, ranging from picking and packing to sorting and transporting goods. They are adept at working tirelessly, with precision, which allows warehouses to maintain a steady flow of operations around the clock. Successful integrations of cobots have been documented across various sectors—from e-commerce giants streamlining their package handling to manufacturers ensuring the meticulous assembly of components.

The real beauty of cobots lies in their role as supporters of human work. They are not here to replace, but to assist. Cobots are engineered to take on physically demanding and ergonomically challenging tasks, which have traditionally put workers at risk of injury. By handling the heavy lifting and repetitive motions, cobots help reduce the strain on human workers, leading to a healthier work environment and increased job satisfaction.

Benefits of human-cobot collaboration

The partnership between humans and cobots in the workplace is not just a technological upgrade; it's a productivity powerhouse. Reports and statistics from across various industries bear testimony to this, with significant improvements in productivity where cobots are involved. Businesses have shared stories of efficiency gains, where cobots have seamlessly integrated into their operations, boosting output and operational speed while maintaining high quality.

Safety and ergonomics have also seen marked improvements with cobots on the warehouse floor. With their precision and consistency, cobots have taken over tasks that are prone to human error, reducing the occurrence of workplace accidents and injuries. The collaborative nature of cobots ensures that the human workforce is less exposed to potential hazards, fostering a safer work environment.

Moreover, the inherent scalability and flexibility of cobots make them an invaluable asset in any operation. They can be reprogrammed and repurposed for different tasks with minimal downtime, making them ideal for responding to changing demands, including seasonal spikes in business activity. This adaptability ensures that cobots can pivot as needed, adding value to businesses that need to be agile and responsive in a fast-paced market.

Challenges and considerations

However, integrating cobots into existing workflows isn't without its difficulties. The initial implementation can present technical and logistical challenges that need to be carefully managed. From selecting the right cobots for specific tasks to re-engineering workflows to accommodate new collaborative processes, the transition requires strategic planning. Additionally, workers may need training to operate alongside these new robotic coworkers, necessitating an investment in skills development and workflow adjustment.

Addressing the human factor is equally important when introducing cobots into the workforce. Managing the response of human workers who may be apprehensive about working with robots is crucial. It's about fostering an environment that emphasizes collaboration and support, not competition. By ensuring a smooth transition and promoting acceptance, companies can harness the full potential of human-cobot collaboration, setting a new standard for innovation and efficiency in the workplace.

The future of cobots in warehousing

Looking ahead to 2024 and beyond, industry experts anticipate cobots will play an increasingly pivotal role in warehousing.

These developments are expected to drive greater efficiency and forge even stronger partnerships between humans and machines on the warehouse floor.

To prepare for a future rich with cobot integration, companies are advised to start laying the groundwork now. This includes investing in the right infrastructure, upskilling employees, and staying abreast of technological advancements. Embracing a culture of continuous learning and adaptability will be essential for the workforce to thrive alongside an evolving fleet of smart machines.

Embracing the cobot revolution

The narrative of cobots in the warehouse is one of transformative potential. As cobots become more adept and integrated, the symbiotic relationship between human workers and robotic assistants is poised to elevate the warehousing industry to unprecedented heights of efficiency and safety. Businesses are encouraged to look beyond the horizon and consider the multifaceted benefits that a strategic human-cobot collaboration could bring to their operations.

As we stand on the cusp of this technological shift, your insights and experiences with cobots are invaluable. We invite you to join the conversation and share how cobots are reshaping your supply chain operations . For those on the path to cobot integration, we offer a wealth of resources and expertise to support your journey. Embrace the change, and let's navigate the future of warehousing together.

For free consultation on warehouse operations, click here.

----------------------------------------------------------------------------------------------

View the full presentation:

WRITTEN BY

Milda Butkeviciute

2024-01-08